NOVA3D Wax Resin for LCD 3D Printer, 405nm 3D Printer Resin for Silicone Rubber Mold Press Print, to Jewelry Design…

$29.99

Make sure this fits by entering your model number.

✅ Jewelry Sample Observation: Ultra precision & high-strength ensure models’ detail clearly display, delicate and perfect. It suitable for bi-component silica gel & low-temp press mold. It not applicable to high-temp castable.

✅ Lowest Shrinkage: Lower shrinkage and great stability significantly reduce printing time with its excellent fluidity, work excellent, which makes the models present much better details than the standard resin or bio resin.

Description

- If you use bi-component silica gel work with our wax resin that it’s going to takes 4 hours to work and no temperature requirement.

- If you use wax resin & yellow gel to make low-temp press mold that it suggest temp requirement is 70-80 degrees, max temp is 90 degrees. Work time is 30 minutes.

- If you wish to have to use silicone rubber to make high temp mold that our wax resin can not work.

- Greatly reduce the printing process appears in the layers waves.

- Awesome details performance for jewelry prints can apply for gold and silver models press rubber.

- High-speed solidify: Shorten the curing time and strengthen the printing efficiency of LCD machines as much as conceivable.

- High Hardness: This resin ensures the strength of molded parts but please don’t cure long time by cure machine to avoid the model does not brittle.

NOVA3D Wax Resin–We make what you wish to have.

Use Tips:

- Shake gently and well before the use of.

- Keep away from children, dust and direct sunlight.

- Wash the models about 30s by 95% or more concentration organic solvent or isopropyl alcohol.

Specification:

- Hardness: 79~88/D

- Tensile strength: 64~72MPa

- Elongation at break: 8~13%

- Bending modulus: 1.8~2.3Gpa

- Heat deflection temperature: 44~47℃

NOVA3D Wax Resin for 3D Printer

Please read the ” IMPORTANT NOTICE” before start printing. It means you fully understand and accept all points is the notice.

Suggest Print Setting:

RGB Resin Printer:

- Thickness of layers: 0.035-0.05

- Bottom Layers: 3~5 / Bottom Exposure Time: 30-40 second

- Normal Exposure Time: 5~8 second

Monochrome Resin Printer:

- Thickness of layers: 0.035-0.05

- Bottom Layers: 3~5 / Bottom Exposure Time: 15-30 second

- Normal Exposure Time: 2-2.5 second

If you use this resin to other lcd printer that please adjust the exposure time and the thickness.

<a href=”javascript:void(0)” data-csa-c-func-deps=”aui-da-a-expander-toggle” data-csa-c-type=”widget” data-csa-interaction-events=”click” aria-expanded=”false” role=”button” data-action=”a-expander-toggle” class=”a-declarative” data-a-expander-toggle=”you’ll be able to get empty jewelry shape by pressing machine, after it cool then cut the rubber, take out the printed jewelry model, you’ll begin mass production.

- Suggest temp an work time to different rubber materials:

- Yellow Adhesive: 70~80 degrees, 90 Max

- Work Time: 30 minutes

- Silicone rubber: 130 degrees, 180 Max

<a href=”javascript:void(0)” data-csa-c-func-deps=”aui-da-a-expander-toggle” data-csa-c-type=”widget” data-csa-interaction-events=”click” aria-expanded=”false” role=”button” data-action=”a-expander-toggle” class=”a-declarative” data-a-expander-toggle=”Commentary: Ultra precision & high-strength ensure models’ detail clearly display, delicate and perfect. It suitable for bi-component silica gel & low-temp press mold. It not applicable to high-temp castable.

✅ Lowest Shrinkage: Lower shrinkage and great stability significantly reduce printing time with its excellent fluidity, work excellent, which makes the models present much better details than the standard resin or bio resin.

✅ Practical Material: Jewelry model printed by NOVA3D Wax Resin can directly act as pressure rubber model, thus you’ll get empty jewelry shape by pressing machine, after it cool then cut the rubber, take out the printed jewelry model, you’ll begin mass production.

✅ Better Adaptability: NOVA3D 405nm wax resin adapt to most LCD, DLP 3D printers, such as NOVA3D Elfin, Bene4, GEM, Anycubic photon, Elegoo Mars and so on. It wish to adjust base on your printer light intensity. (can’t casting but it suitable for silicone mold).

✅ Quality Guarantee: We pride ourselves on providing caring service, both before and aftersales. Our beef up will respond to all inquires within 24 hours, with the exception of some holidays.

Related Products

-

Sale!

Eryone – Signal Gray PLA Filament

$22.99Original price was: $22.99.$18.99Current price is: $18.99. Buy Now -

XYZPrinting Black ABS Filament | NFC, Dimensional Accuracy +/- 0.02 mm, 600g Spool, 1.75 mm

Buy Now -

Bilway – Carbon Fiber PLA Filament

Buy Now -

CooBeen – 4 Pack Silk PLA Filament Bundle

Buy Now -

OVERTURE Nylon Gray Filament (1.75mm)

$32.99 Buy Now -

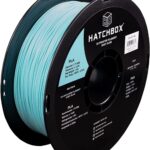

HATCHBOX PLA 3D Printer Filament, Dimensional Accuracy +/- 0.03 mm, 1 kg Spool, 1.75 mm, White

$18.92 Buy Now -

eSUN – Black ABS Filament

$22.99 Buy Now -

Anycubic Black Plant-Based Resin (1000kg)

$31.99 Buy Now -

Geeetech – Silver PLA Filament

$19.99 Buy Now -

DR.3D Water Washable 3D Printer Resin, 405nm Resin for 3D LCD Printer with Low Oder, Fash UV Curing Rigid Photopolymer…

Buy Now -

Transparent Purple PLA Filament

Buy Now -

LEE FUNG ABS 3D Printer Filament White

$18.99 Buy Now -

Ultimaker 3 NFC ABS Filament – Green

Buy Now -

Sale!

Monoprice – Black PLA Filament

$48.00Original price was: $48.00.$24.99Current price is: $24.99. Buy Now

Reviews

There are no reviews yet.